|

TOP END MACHINING SERVICES |

Click here to go back to our machine shop index.

|

|

Welcome to the 70's. We see big bore cylinders from the olden days like this all the time. This is another example of what not to do!

First:

Secondly:

Third:

Fourth: |

|

|

O-Ring Oil Feed Modification There seems to lengthy discussions about head gasket thickness, o-ring thickness, cylinder block thickness, oil leaks, oil starvation to the camshaft, etc. Anyway, here is what we have been doing for decades. We install dowel pins so the o-rings stay in place. We have seen many circumstances where people have installed oversize o-rings or thinner gaskets and the o-rings worked their way inwards, causing numerous problems. Honda used this procedure on oil lines and other areas. Not sure why they didn't do this to the top of the cylinder.

$49.00 (Parts and labor)

|

|

|

Cylinder and head surfacing.

This machining

offering is done for a couple of reasons.

|

|

|

Upper Case Boring This procedure is needed for big bore applications when large sleeves are installed. $100.00 (Stud removal is extra $)

|

|

|

Big Bore Cylinder Work

Includes: Glass bead cylinder, remove sleeves, surface bottom of

block, bore and hone block and install sleeves, surface top,

bore and final hone. $375.00

|

|

|

Bore and Hone (Budget Version) Includes: Surface top, bore and hone. Glass beading not included. (Can include torque plates for another $60.) 1st over $150.00

Bore and Hone (Deluxe Version) Includes: Glass bead cylinder, surface top, install (6) Heli-coils with race proven 12mm long coils for added support, bored, beveled and final honed. (Can include torque plates for another $60.) $239.00 |

|

|

Torque Plate Bore & Honing Torque plate bore and honing procedures will simulate your motor being together. This procedure is used in almost every high level machine shop in the country. $40.00

|

|

|

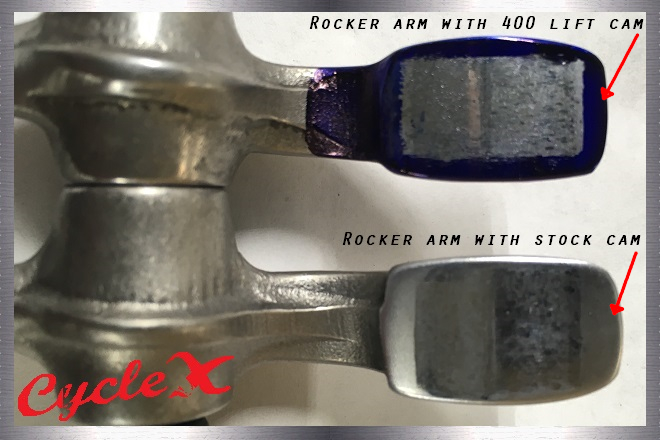

Rocker Arm Lightening Same technique used in our vintage road racer. $119.00

|

|

|

Honda CB750 Rocker Arm Refurbishing Hard

welded and ground to perfection. $492.00 (Set of 8)

|

|

|

Tech tip: Lighter valve trains can be super beneficial for performance increases when "combined" with 5mm valve kits, bee-hive springs, titanium jam nuts and lightened rocker arms. The above photo shows the excess material that can be removed to get the full benefits of lighter weight valve trains. Lightening the rocker arms near the pivot shaft would be a waste of time. Your goal is to lighten as far out as possible.

|