|

#DIY-1 |

|

DO IT YOURSELF LOWER END PAGE |

Introducing the "do-it-yourself" Honda cb750 motor lower end assemblies:

We have eliminated the confusion, potential

for error and need for special tools with our new crankshaft and engine case

offerings.

Confusion? .... because the owner's manual

charts, articles from the 70,s and plastic gauge procedures are crude and

inaccurate.

Potential for error? .... check-out the

facebook posts from last April and March to see how the engine cases need help.

Engine cases:

Clean cases and remove studs.

Chase all 6mm and 8mm threaded holes with

our thread reforming tool.

Install blasting engine covers and blast

with medium grit.

Remove covers and inspect cases for flaws.

Apply Dykem layout fluid to the main

bearing areas and begin our line-lapping procedure.

Measure the crankshaft journals and install

our testing main bearings. Torque and measure clearances.

Occasionally some of the bearing clearances

are still to tight .... even with yellow bearings .....

but we are able to focus

on the problem areas with our special lapping tool .

Final test .... install the crankshaft in

the cases and torque to check rotation and endplay.

Crankshaft:

Measure journals and check the crankshaft

for straightness.

Install blasting journal covers and blast

the crankshaft.

Remove blind hole ball bearings and

cleanout the 50 years of sludge.

Enlarge con-rod oil holes and relieve for

improved oiling.

Machine main bearing journals for more

available oil.

Micro polish rod and main bearing journals.

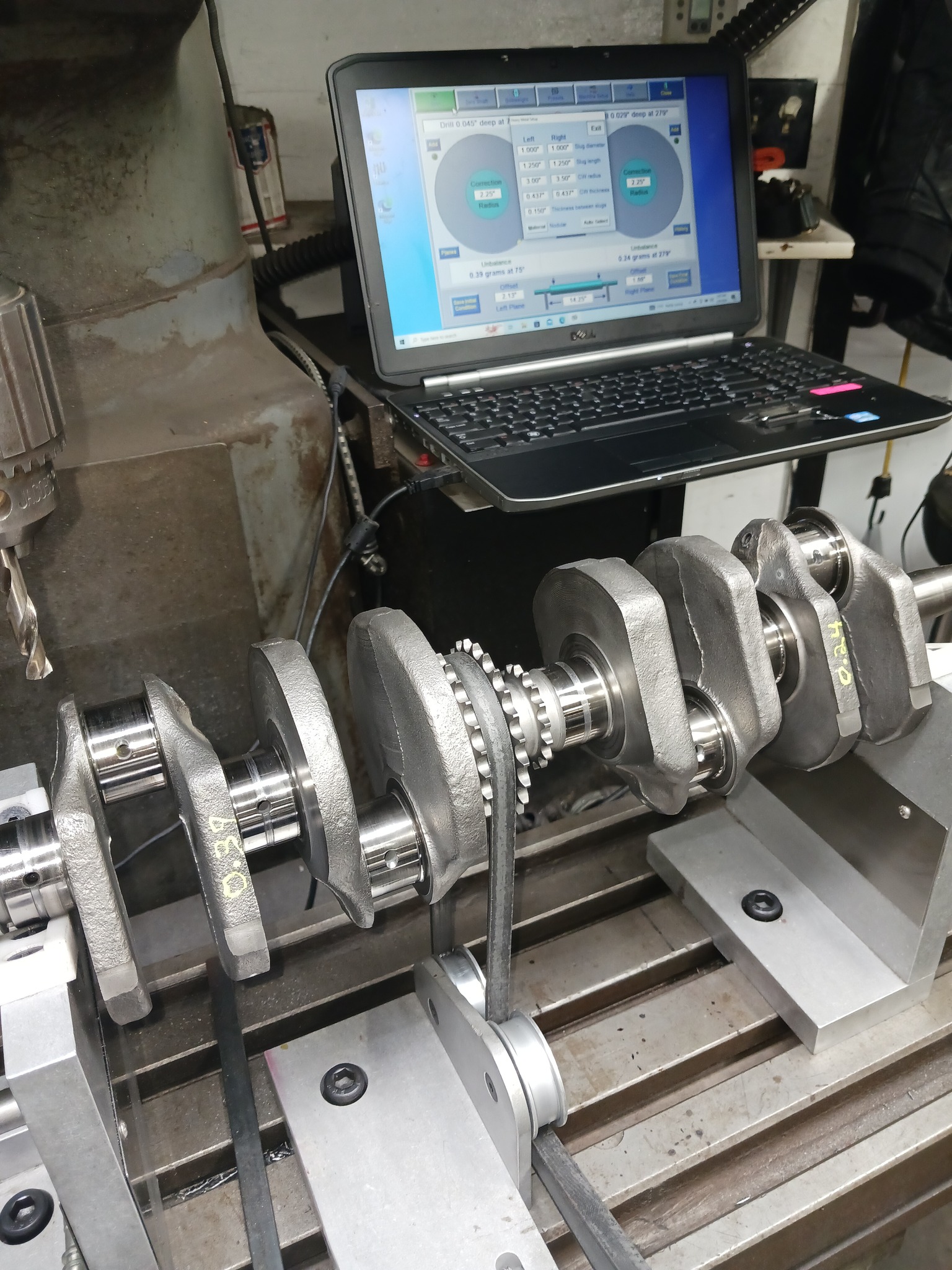

Balance to absolute perfection with our

state-of-the-art balancer.

Connecting rods:

Measure clearances and install

refurbished stocks rods, "super-stock" rebuilt connecting rods with Cryo treatment or measure clearances and install our Generation 4 high performance connecting rods.

|

#DIY-1 |

|

#DIY-2 TOTAL

$ 2122.98 |

|

#DIY-3 All of the above world class

labor and procedures. TOTAL $ 2367.98 SOLD -BUT CAN BE DUPLICATED |

|

.00 #DIY- 4The highest level race or hot street lower end. 1976 and under engine cases (noted for rear chain alignment) All of the above mentioned world class procedures. Engine cases have been "line-lapped" with our race proven procedure to insure straightness and roundness. Standard weight crankshaft is perfect for nearly all foams of racing and street life. Refurbished, resized Carrillo connecting rods fitted (.0015) with our "dry film" coatings Top case is bored for possible big bore sleeves. Relocated rear crankcase breather. Breather windows between 1&2 and 3&4 cylinders. Main bearings are fitted (.0015) with our "dry film" coatings (perfect) Labor: $1500.00 Parts: Refurbished Carrillo connecting rods (new ARP bolts) ... $899.00 Breather windows, lower windows and modifications ... $150.00 Coated main bearings ... $208.99 Coated rod bearings ... $159.99 Engine case and crankshaft core charge ... $150.00 TOTAL $ 3067.68 SOLD -BUT CAN BE DUPLICATED |

|

.0 #DIY- 5Built for big horsepower!!! All of the above mentioned labor and procedures. Engine cases have been "line-lapped" with our race proven procedure to insure straightness and roundness. Main bearings are fitting with race proven coatings. (perfect .0015 clearances) This crankshaft is fitted with the Gen 3 CycleX connecting rods .... sized and fitted with race proven coatings (perfect .0015 clearances) Cleaned and ready for assembly. Procedures performed on 1969-76 cases. (noted for rear chain alignment purposes) Labor: $1500.00 Parts: Gen 4 connecting rods (ARP) ... $689.00 Coated main bearings ... $208.99 Coated rod bearings ... $159.99 Engine case and crankshaft core charge ... $150.00 TOTAL $ 2707.98 |

|

#DIY-6 TOTAL

$ 2122.98 |

|

#DIY-7 TOTAL

$

1858.99 |

Above labor:

Notes, observations and race proven techniques:

Words of Wisdom from a Honda Wrench

In 1970, Italian born Eraldo (Harold) Ferracci went to work for Chiaccio Motors in Riverside, New Jersey. During the normal 9:00 to 5:00 work week, he works as their shop foreman. But come the weekends, and he can be found at one of the National Drag Racing Events from California (Freement or Irwindale) to Kentucky (Bowling Green) to Florida (Tampa or Orlando). Eraldo started drag racing Hondas in 1970 with a slightly modified CB 750. From that time on, he's been running in the modified classes and more recently, in the "B" Gas class 1162 cc. In 1975, when the smoke finally cleared, he came out number 5 in Overall National Competition with his fastest time posted in Florida at 9. 36 E.T., 146 MPH. The racing world is nothing new to Eraldo. In Italy at age 11, he worked part time for then World Champion 500 Gilera rider, Libero Liberati. At age 18, he went to work for Benelli R & D and was part of their factory road racing team from 1962 to 1966. Space prevents us from listing all of his activities for the "competition". But from 1963 to 1964, he was National Champion in 125 cc Class. Benelli brought him to the U.S. to assist with their mini-bike marketing program and, in 1967, to assist their road racer Bertorelli. Later, he worked with others to organize Benelli's training center and service department. But his racing activities continued including flat track, TT as well as road racing. Riders he has worked with include Gary Nixon, Dick Mann, Ronnie Rall, Eddie Wurth and Elliot Schultz.

Besides his current racing activities, Eraldo is involved with Ravesi, Norris, R.C. Engineering, Venolia and MPC in developing different types of mostly top end related parts. He does all of his cylinder head work himself.

Eraldo offers us some words of wisdom for the serious engine builder. He tells us that anytime you are installing a crank on a CB750, be it a new part or one you're going to re-use, you must measure each main and rod pin for out-of-round or taper with an outside micrometer. After that's done, lay the crank alone without rods in the cases with the bearings that are called for from the chart. Lay in your pieces of plastigage; put on the lower case half; and torque to 16 ft. lbs. Eraldo does this plastigage check four different places around each main and rod journal.

After cleaning all traces of plastigage, again lay in the bare crank. Don't get any oil between bearing shell and cases. Put on bottom case half, torque all the main bolts up to 10 ft. lbs. and hand spin the crank, making sure of its free rotation. Torque all bolts another 2.0 ft. lbs. and again check for free rotation. Eraldo keeps torquing in 2 ft. lb. increments until he reaches 16 ft. lbs. If you can find one particular bolt that's keeping the crank from spinning, note on the case the level it can be torqued to without stopping the crank's movement. On final engine assembly torque it to this figure. As long as it's above the 12.0 ft. lb. level the bolt will stay and not cause any problems. Measure, checking and rechecking is essential if you expect the engine to perform reliably, especially under the extreme conditions of racing. "Above all" according to Eraldo (Perhaps paraphrasing an old Italian (?) saying), "cleanliness in engine work is next to Godliness".

We disagree.

RANDOM PHOTOS

Using the chart from a

Honda cb750 manual is something we don't do.

Using plastic gauge is a very crude way of measuring.

Torquing main bearing bolts to different foot pounds is just

another indication that the cases are not true or round.

Installing the crankshaft in the cases and torquing to "full

torque" to see if the crankshaft rotates freely is our final

check.

More photos coming soon.